This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

proofread

Accelerating the practical application of next-gen batteries that are fire-resistant through dual-layer coating

Professor Hongkyung Lee of DGIST's Energy Science and Engineering collaborated with Dr. Chanhoon Kim's Clean Energy Conversion Group at the Korea Institute of Industrial Technology (KITECH) to introduce a stabilization technology for unstable battery systems through the adoption of a dual-layer coating method. The work is published in the Chemical Engineering Journal.

Lithium metal, renowned as an ideal anode material for batteries, has a theoretical capacity ten times higher than commercially used graphite, thereby allowing the creation of batteries surpassing energy density limits of existing secondary lithium batteries. However, lithium-ion batteries pose fire and explosion risks during overcharging or over-discharge, thus creating significant constraints for their use in electric vehicles and portable electronic devices. Consequently, research on safe alternative technologies is being actively pursued.

Aqueous zinc batteries, known for their high energy density and environmentally friendly characteristics, are drawing significant attention in the energy storage system (ESS) sector. Regarded as a safe alternative technology, efforts to enhance their activation are deemed crucial. However, the commercialization of aqueous zinc batteries has yet to be achieved due to challenges such as zinc dendrite formation, hydrogen evolution reactions, and zinc corrosion.

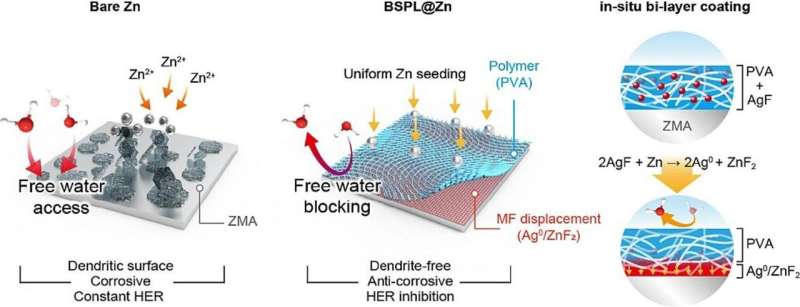

To address these issues, Professor Lee's team introduced a novel dual-layer coating technique employing both polymers and inorganic materials. This process involves simultaneously applying metal fluoride and polymer solution onto zinc metal. The metal fluoride is placed in the lower layer, while the non-reactive polymer layer is positioned above.

The upper polymer layer effectively prevents direct contact between water and zinc metal, thereby suppressing hydrogen evolution reactions by over threefold and preventing zinc metal corrosion. Meanwhile, the metal fluoride layer underneath exhibits zincophilic properties, effectively inhibiting zinc dendrite formation.

Professor Hongkyung Lee from the Department of Energy Science and Engineering stated, "This research has innovatively addressed the persistent challenges of aqueous zinc batteries, including zinc dendrites, hydrogen evolution reactions, and zinc corrosion, through a simple dual-layer design. We anticipate that this technology will expand to various systems utilizing metal anodes, beyond just zinc."

More information: Jaewoong Han et al, In-situ coating of metal fluoride/polymer bi-layer protection for dendrite-free, anti-corrosive Zn-metal anode, Chemical Engineering Journal (2024). DOI: 10.1016/j.cej.2024.149881